Designed to withstand high temperatures, the iS system does not need a separate air conditioning or cooling system to operate, making it smaller than most other emissions monitoring systems on the market, and making it much easier to install. This means it can be installed in the engine room or even in the funnel space easily. Also, as the iS does not need A/C, there is no need for refrigerant gases. These are harmful to both human health and the environment, and their disposal is classed as Hazardous.

As the iS platform is so robust, it does not experience the drift in calibration at high temperatures that some other systems experience which often leads to more frequent calibrations being needed. Saving you money and time in needless calibration gas orders, and service visits.

Download the spec here or talk to the team here if you any other questions about the Emsys-iS platform.

The iS platform’s size is one of its greatest assets. At only 55kg and about the size of a suitcase, the system is compact and easily installed on retrofits and newbuilds, where space is restricted.

More specifically, the system’s size and weight mean it can be installed at the top of a stack without interfering with a vessel’s stability. The closer to the measurement point an emissions monitoring system can be installed, the faster the cycle time and more efficient and accurate the measurement of emissions.

Download the spec here or talk to the team here if you any other questions about the Emsys-iS platform.

In its simplest configuration, we can supply an Emsys-iS with SO2/CO2 QCL laser sensor and a basic Type Approved software package to meet the minimum compliance standards at a highly competitive price. However, the iS can measure any number of gases for whatever the shipowner’s needs. Whether you need to measure NOx, SOx, CO2, SO2, CO, CH4, or NH3, (or all of the above!) these are all modular options of the iS platform. The iS platform can cover any specialist needs, and can cover up to 16 points, with the added benefit of a range of reporting options using our own EmChart software.

There are many reasons why you should consider mass emissions as important for your emissions monitoring system, head to our mass emissions page to find out more, download the iS technical specification here, or talk to the team directly to find out more here.

The Emsys iS platform is a hardwearing system and with our IP56 option can be easily sited on the weather deck. This is a significant installation benefit for retrofit scrubber applications as it minimises Heated Sample Line lengths and offers more options when finding a suitable location for installation.

The weather deck option was developed after a shipowner’s request for a more robust analyser, because many scrubbers are installed on the outside of a vessel’s superstructure. The IP56 option simplifies installation as well as being able to install closer to the measurement point, shortening cycle times.

The iS was designed from the beginning with vessels in mind; hence features such as its size, weather deck option, and no A/C unit. Emsys understands the conditions facing a vessel and it’s onboard equipment and designed an EMS system accordingly.

Download the spec here or talk to the team here if you any other questions about the Emsys-iS platform.

The Emsys-iS platform is partly so efficient because of it’s Hot-Wet measurement capability. Hot-Wet measurement is when stack gas is measured without conditioning. The gas is drawn into the iS’s QCL laser sensor via a vacuum pump and returned back into the stack without any other treatment e.g. with permeation dryers. This avoids a major failure point of other CEM’s based systems and contributes to the small size of the iS.

This is especially useful for fast measurement; typically, the iS can measure SO2 in 9 seconds and CO2 in under 1 second (T90). The lack of conditioning or treatment of gases speeds up the entire measurement process, and one iS enclosure can typically measure 4 scrubbers within the allowable cycle time. This is a massive advantage for shipowners with multiple scrubber measurement systems.

Download the spec here or talk to the team here if you any other questions about the Emsys-iS platform.

The iS platform is very low maintenance because it measures the NO2 directly, eliminating the need for any expensive, disposable NOx Converter catalysts. The iS also needs no gas conditioning systems, e.g. permeation dryers which have expensive annual consumable parts. Additionally, the iS produces no sample condensate which is difficult to dispose of onboard due to its pollutant state and can mean more maintenance.

When maintenance is required, we have a team of specially trained technicians who can offer a range of through life support options including onboard visits, remote support, and crew training. Talk directly to the service team here to find out more.

Visible Smoke / Particulate Matter (PM) sensors are a highly useful tool for shipowners. Class Societies have many environmental notations which require fitment and operation of enhanced monitoring equipment above and beyond those detailed in IMO regulations and guidelines. The benefit to the owner being a vessels ‘gold standard’ which should make it easier to charter.

Not only do they help with an increasing amount of Class Society regulation in this area but are especially important for environmentally sensitive areas. Regulations are increasingly common, with US ports having localised smoke regulations and places such as Alaska have strict Visible Smoke and Particulate Matter Density laws and regulations which apply to all ships not just cruise ships. The resultant penalties and on-cost delays on account of breaking regulation can be significant.

Public health is also a consideration shipowners now have to make. PM is generically covered under IMO MARPOL Annex VI regulation 14. However, an increasing focus on PM is happening due to its direct effect on human health. Modern changes to engine design have changed the size of PM particles produced, from larger particulates that naturally drop out over the sea to the finer particulates that stay airborne and are considered extremely hazardous to health. Various international studies have determined that emissions from ships are causing premature deaths, this increased scrutiny is forcing regulators to determine how to tackle this issue. Reducing the sulphur content of fuel has certainly improved matters and the introduction of the 0.5% global sulphur cap in 2020 improved matters more.

Additionally, an Emsys-PM can be used to monitor smoke in the boiler combustion process, providing feedback and allowing fuel-air optimisation and early warning of visible smoke during load changes. The fitment of smoke density monitors also may assist vessel owners in compliance with OCIMF TMSA accreditation.

Between the environmental concerns and regulations, or the technical benefits of installing a Visible Smoke / Particulate Matter (PM) Monitor, Emsys Maritime has made it easy to get a quote and install a system onboard quickly. Talk to us today for a quote.

Using cross stack technology, the Emsys-PM can be supplied for newbuilds or in kit form for retrofit to existing vessels. The kit includes all items such as the sensor heads, flanges, air purge blower, cabling and detailed installation instructions to allow the ship’s crew to install it themselves.

Like all Emsys systems, we designed the PM monitor with hands on experience of what a vessel and its onboard equipment goes through every day. As well as competitive lead times, the PM system is competitively priced, and very compact. Making installation quick and easy. The PM’s ability to integrate into existing automation systems means it can be supplied as a standalone system without prior purchase of our other technologies.

Designed with shipowners in mind, see the full spec here, or talk to our team today to see how soon we can meet your Particulate Matter monitoring needs.

The sensors are virtually maintenance free. Housed in robust stainless steel IP65 enclosures, they only require occasional cleaning of the lens reducing workload on the vessels crew. Emsys understands efficient and low-cost options shouldn’t sacrifice accuracy or reporting options, so the Emsys-PM was designed specifically to be easy to maintain. As well as being incredibly compact, the PM still offers a range of reporting options, and easily integrates into all existing automation systems. Compact and clearly set out, maintenance is minimal ensuring low through-life costs. Our crew training options together with specific design features make Emsys-PM maintenance incredibly efficient.

To see what crew training options can work for you talk to the technical team here or download the spec of the Emsys-PM here.

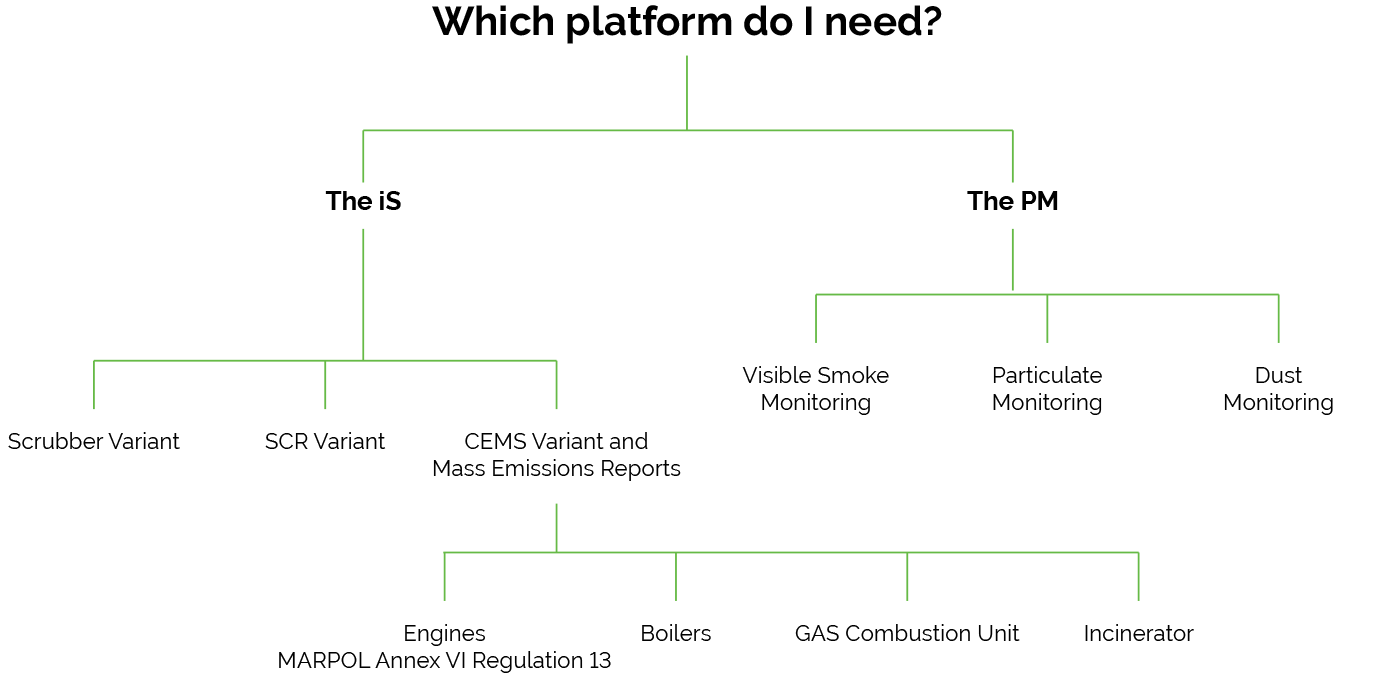

We supply patented technology to accurately monitor all types of marine engine (2-stroke and 4-stroke diesels), marine boilers, waste incinerators, and gas combustion units (GCUs). We have experience working with differing types of technology such as open loop, closed loop, and hybrid scrubbers.

We have worked hard to ensure Emsys is approved for every mandatory maritime air emissions regulation and can meet the requirements of most environmental Class Notations. We can measure NOx, SOx, CO2, CO, CH4, NH3, SO2, Opacity & PM and our unique ‘mass emissions’ capability helps shipowners measure the total mass emissions inventory (kilograms or tonnes) of all emittance.

Applications include MARPOL Annex VI compliance, Exhaust Gas Cleaning Systems (EGCS) ‘scrubber’ compliance, IMO Tier III NOx compliance (Selective Catalytic Reduction Systems – SCR), mass emissions measurement including methane slip, EU Monitoring, Reporting & Verification (MRV)Regulation, US EPA Air Permit applications for deep-water drilling and Visible Smoke, Dust, and Particulate Matter measurement.

There is a lot to consider when it comes to installing the right monitoring equipment, including the EU and international emissions and energy efficiency regulations, class notations, environmentally sensitive areas, an increasing interest inParticulate Matter monitoring and Visible Smoke concerns.